Type Three Tuning Page -- Transmission

Please select the area of interest:

Stock

Automatic: A complete rebuild kit for a type III A/T is $90 and includes

all seals and clutches. The only things not included are the brake bands. These

are about $15 each new.

For purchasing these parts a recommended company is "ADC Distribution Group".

Most parts in the kit were original VW (I don't know how they do it). They can

also build torque converters from scratch.

Go to their Locations page at www.atcdg.com

to find the location nearest you.

Another place for tranny parts: http://www.makcodistributing.com/

Here is the consensus of the group regarding towing: Tow with all wheels off

the ground.

Manual Transmission

Can be towed with the rear wheels on the ground without any problem. The tow

dollies (two wheels on the ground) are a bit less stable than the full trailer

(all four wheels off the ground), but are substantially lighter if towing

capacity is an issue. Plan on the T3 to being 2200lbs. Add the weight of the

trailer or dolly and check your capacity.

Automatic Transmission

Should be towed with all four wheels off the ground. If this is not possible,

then the drive shafts should be disconnected at the transmission. The automatic

transaxle lubrication pump is driven by the "running" engine. If I remember

right, the manual recommends towing it less than 30miles at no more then 30 mph

in emergency situations or towing backwards (front wheels only on the ground).

Towing backwards (front wheels only on ground)

Not recommended except for short, low speed tows. The caster is all wrong when

going backwards and the tires would tend to wander, putting a lot of stress on

the steering lock.

The Type 3 automatic is a very solid transmission. They are known to go for over

100k miles with no problems. The worst problem can be the torque converter seal

leaking, and there is a trick to fixing that: Put 2 seals in it. They did not

like being run low on fluid. The transmission is actually made by Borg Warner,

and the same basic guts are still used to this day by VW and Audi. Auto-Sticks

were good too if properly maintained, and adjusted. Just a little harder to work

on. The auto-stick was just a manual trans that had been modified with a vacuum

clutch and torque converter.

Russ Wolfe

Factory trained VW mechanic since 1965

http://wolfenet.net

Automatic circuit diagram.

MT gland "nuts" are commonly available since beetles used the same part, but the type 3 AT ones are not. However, you can convert an MT to an AT by knocking out the bearing inside and shaving 2mm off the thickness of the head. That might be easier than trying to find the correct part somewhere and getting it shipped to you.

In general, they are infinitely reusable.

Jim Adney

From the VWType3.org email list

More automatic info taken from The Shop Talk Forums, author Ray Greenwood.

Content has been edited for readability:

It really helps the drivability if you properly adjust the automatic, including

main pressure and bands. Get the Bentley. Rarely does anyone make the proper

adjustments. They run very well when adjusted properly. Anytime you greatly

change the engine -- thus creating a new vacuum signature -- you must re-adjust

the modulator valve.

While you have the tranny out, replace the seal between the transmission and

final drive. Takes about 10 miutes and 4 bolts. They only last 7 years or 70k.

When they fail the tranny is toast within minutes.

The transmission uses hydraulic pressure valves to control the shift. Those have

an rpm governor that helps to keep the hydraulic pressures stable. Also, a

corrective device is the modulator valve. That is vacuum operated but is also a

tuning device. It is a further method of hydraulic pressure to the governor

stable. They work as a group. The modulator valve is an input of sorts for

throttle position and load while the governor sets range and rpm points. I don't

have my book close to me so I can't remember at which pressure the modulator

valve modulates. But, the pressure can be checked with gauges and adjusted on a

turbo engine to be able to run correctly. It may be worth looking at the Bentley

for soemthing like the Saab turbo or the Audi turbo to see where in the manifold

they pull their vacuum from and what kind of readings are required. Usually you

do not adjust to vacuum readings. You generally drive and adjust using a guage

and a long hose. In the Bentley manual, it shows several points on the tranny

case that have plugs in them. These are just for checking pressures

The Type 2, 3, and 4 automatics all use a Type 003 (Type 3) geabox. Now, that's

the automatic portion of the transfer case mind you. The Type 2 uses a different

differential section. The Type 3 and Type 4 use the same differential case. But

bear in mind that there is an early and a late output shaft style for the

differential cases. That being said, ALL of the Type 003 automatics in Types 2,

3 & 4 have a cast iron differential gear carrier. Freaking work of art! The case

is aluminum...or magnesium...whatever, but after you pull the tranny and the

torque converter you will see the cast iron plate with about 8-10 bolts behind

the torque converter.

Remove the stub axles and the 10 bolts behind the torque converter and the whole

differential carrier, complete with meshed pinion shaft, will drop out in your

hands. The bearings, pinion shaft, differential and ring gear assembly are

totally separate from the tranny case in their own cast iron carrier. They do

not transfer their load to the aluminum case except at the 10 bolts on the bell

housing, with rotational force.

Hal Sullivan wrote:

The early Bus ('73-'75) automatics and the Type 3/4 automatics are both "003"s.

The Bus final drive (differential carrier) is quite different from ours, but the

actual transmission is nearly identical.

This all goes out the window with the '76-later Bus & Vanagon which used the

010/090 automatics; those are a different beast altogether.

Custom

Mike's advice for installing a Porsche 911 or 914

5-speed tranny.

The 912E used a Porsche 923 transmission (only about 2000 examples were ever made).

A Porsche 901 transmission is a semi-common conversion to VWs. It requires

a bit of custom fabrication, but not a whole heck of a lot, and it is far

cheaper than a Berg 5-speed or equivalent. The 1964-69 911 and 912 cars

used "901" and "902" transmissions, respectively (same basic construction,

just some had 4 and some had 5 speeds). The 1970-71 911 used a "911"

transmission, which is a modified 901 setup. Slightly stronger case.

The Porsche 915 transmission is a whole new animal - all different internals

and case and everything. It's much more durable than a 901. However,

Porsche decided to use a pull-type clutch on these. That means that instead

of activating the clutch by pushing a throw-out bearing from the outside in,

it pulls it from the inside out. This makes for a big hurdle for VW

conversion. There were a couple different variations spanning their 1972-86

use in the non-turbo 911.

The Porsche 923 transmission is basically a 915 with a 901 bellhousing. How

convenient :-). It was used in the one-year-only car, the 1976 Porsche 912E.

Shad Laws

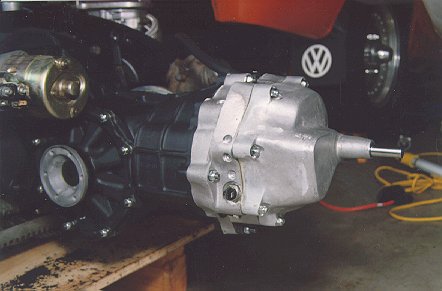

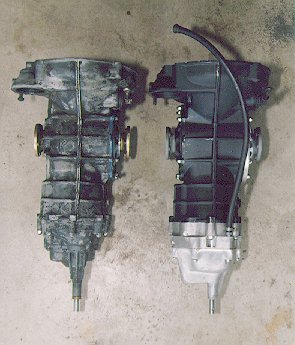

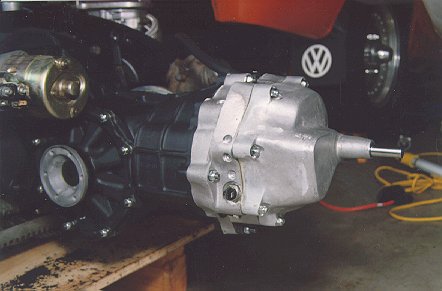

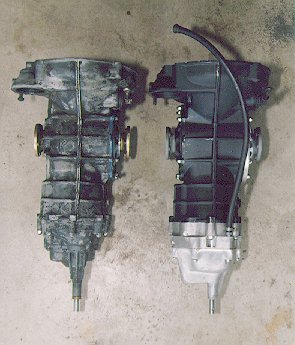

The Gene Berg Five-Speed Tranny

A five-speed transmission is a great modification that clearly makes an

air-cooled VW stand out (provided people know about it, heheheh). I created my Gearing Analyzer to help me figure out my gearing.

Regearing a transmission is no simple task. Great care must be exercised in

selecting a combination of gears, ring and pinion (R&P) and wheel diameter. The

Type III is particularly difficult to work with since the fan cannot be changed

like an upright motor (like the Type I) to vary the cooling intake. If you start

deviating from stock too much you may start to have cooling issues.

Here is the 2.5Mb MS Word document I

sent Clyde Berg on what my mechanic (Doug Powers, retired) and I did.

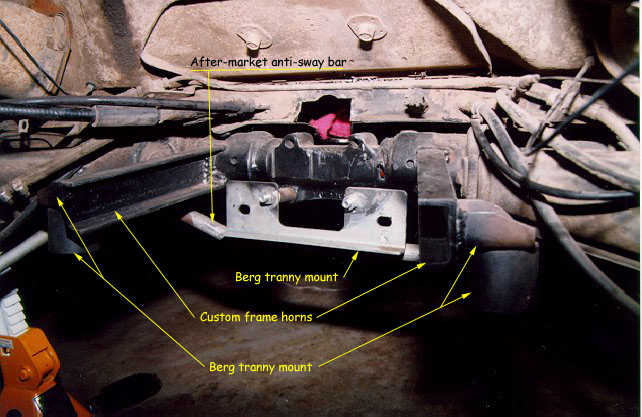

>I see you have

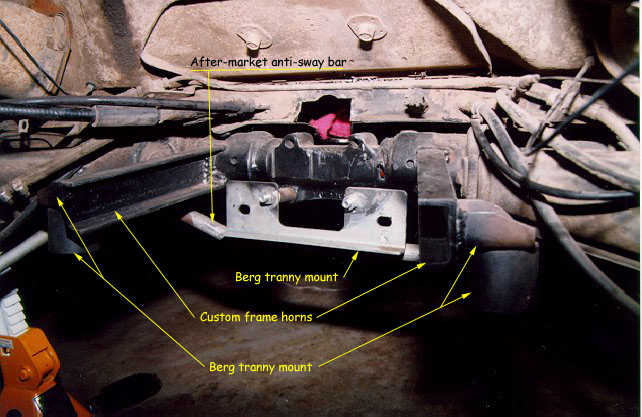

>IRS. And from your note I understand that you fabbed your tranny "horns"

>by using some "u" channel...did you use the stock engine "carrier" or

>did you modify a berg engine support? What do you think about cutting a

>set of horns out of a donor pan and welding them in vs the "u" channel?

Yes, I still use the engine carrier. I doubt the stock frame horns would work

since they extend further back than the Berg tranny mount. However, you *may* be

able to modify their tranny mount to the stock frame horns. You need to have all

the parts and find out for yourself (kind of a spendy way just to figure

something out :) or you might call up Gene

Berg Enterprises and ask to speak with Clyde Berg about it. He's very busy

so try to have your questions thought out ahead of time.

Glenn Ring's 5-speed for

his Type I. Shows good pictures of the 5-speed kit.

My Conversion from an Automatic to Manual Transmission by Craig Woolston

(Copied from the TYPE III email list)

Overview

Remove engine and automatic tranny, drill two holes in firewall, drill shift

tube access hole, replace pedal assembly and shifter assembly. Add clutch cable

tube, cable and manual transmission. Put engine back in and drive. Sounds easy

enough, eh?

Background Notes

Probably what made this the easiest was having a donor Manual transmission car

sitting in the weeds beside the house. The donor was a 1969 rust bucket Square

and receiver was a 1970 Square. So it was easy to check measurements and look at

how it was done. But I believe that it wouldn't be that hard if you didn't have

an example sitting beside your car.

Heavy Metal

After removing the engine and the automatic transmission you can now get to the

firewall and if you leave the car on the jack stands from removing the engine

you can also get to the underside of the car much easier. Since I had the donor

car sitting right next to the receiver I could do quick compare measurements but

I believe if you strip the donor car of it's parts you could do all the

measurements up front and then never need the donor car again. Therefore I will

only be giving approximate measurements here since I didn't ever write them

down.

So with your electric drill and a 1.5" holesaw drill a hole in the firewall for

the shift tube to exit the tunnel to the transmission. Note here that the hole

extends below the firewall so that it's not a complete circle in the firewall.

That way it's just like stock. With a 3/8" drill, drill a hole next to the

throttle cable tube for the shift cable tube.

Since we are to the clutch cable tube I will give my humble opinion on my

solution. I was told this was the hardest part, involving welding, sweating,

cursing and on and on. After close inspection I decided to use 3/8" stiff copper

tubing. This is the only non-stock item in this conversion.

The 3/8" stiff copper tubing is a little uncommon so your local Home Depot won't

have it. I got mine from the local plumbing supply house. What's interesting

about this tubing is it's 3/8" OD not ID like the stuff you get at Hope Depot.

I'm not a plumber but the guys at the plumbing shop told me that when you get to

3/8" stiff tubing and below the diameter is measured as a OD and no longer a ID.

1/2" and above is measured ID.

The Bowden tube (now I remember what's it's called) fits right over the copper

tubing that I cut to stick out from the firewall the same amount as the donor

car. Unless the copper tube is secured to the pan, the tension on the cable will

push it forwards. It must be secured, or perhaps it just moves until the sleeve

on the front end of the Bowden tube slides forward enough that it is stopped by

the firewall. If your tube slips, it will change the slack in the Bowden tube

and this will change the clutch action.

Note by Jim Adney: "I would be concerned that this will not last. How thick is

this flat panel that is now taking this stress? I suspect that it will slowly

deform until the Bowden tube pushes through. This is why this tube is securely

anchored in the original version. To do this properly it must be steel so it can

be welded to the bulkhead and the tunnel." The clutch action was confirmed by

the author to be changing.

As it turned out this was a fantastic size as when this got installed it snapped

into the holders in the tunnel and didn't require any external fastening. It is

a little bigger than the stock size but who cares, there is plenty of room in

there. We just needed a guide tube for the clutch cable anyway.

Next with a 4" holesaw drill a hole in the underside of the car having the

radius of the hole just tangent to the firewall. You can then use a grinder to

elongate the hole to match the cover from the donor (which I did), but in

retrospect I don't think that it is necessary and the cover hides the hole just

fine. Plus you have avoided all the grinding. Using the shift tube cover as a

guide drill holes for the cover to mount to the underside of the car. Since the

cover hides the hole, no one would ever know it's not stock.

That's all the heavy work. I'm assuming that all cars come with a front access

port in the tunnel.

The Transformation

The first thing to install is the clutch cable tube. As I mentioned above mine

just snapped in, no mess, no fuss. You do need to cut it to the correct length

so there is slight overhang on the firewall to pickup the clutch cable tube from

the firewall to the transmission.

Next remove the old pedal assembly. Remove the old shifter. While all this is

off I threaded the shift cable down the new tube. This can really be done

anytime but it was easiest right then. Now I'm also assuming that all cars come

with the same tunnel mount for the shifter as mine did. And that was VW

converted the normal manual stick shift mount to a automatic mount using an

adapter plate. Anyone know if this is isn't true? (Answer: The first AT cars did

not have this feature. It only started in 70. I think earlier cars will be

harder to convert. ~Jim Adney)

Remove this plate. Now in order to convert the tunnel to accept the manual shift

stick mount you need some nuts for the bolts to screw into. For you welders out

there this is probably a simple job but I hate flames so I copped out and used

some JB Weld. I know, I know it's not the best but I think it's okay for this

job. You just need something to hold the nuts while you get the bolts started

later. You could probably get a nut and wrench on them later through the front

access port in the tunnel but that is a lot of arm twisting. Speaking of the

access port...

Next remove the front access port to the tunnel as well as the spare tire and

the access port in the front fender. You probably already know this if you

stripped the donor car yourself rather than bought the donor parts already

removed. Insert the shift tube through all these holes. When the shift tube is

to the shifter hole you need to feed it through the shift mount.

Next bolt the shifter mount to the tunnel and install the new pedal assembly.

Connect the shift cable to the pedal through the front access port. Bolt the

shifter down and then start thinking about making engine noises since were

almost home free.

Install the transmission. Connect the shift tube to the transmission through the

4" access hole already drilled. Install cover over access hole. Install the

shift cable tube between firewall and transmission and bolt to transmission.

Adjust the sag in this tube per VW service manual.

Remove the old flex plate from the engine. Throw the torque converter as far as

possible making sure it does land on your toes. Install the new flywheel, clutch

disc and pressure plate. Get the plastic spline tool to line this stuff all up

as it is much easier than eyeballing it. Can anyone actually do that and get it

right? And finally put the engine in the car. Adjust the clutch and go for a

test drive. Yea!!!

I have to admit that these cars are a lot more fun to drive with a stick. I wish

I did this conversion years ago but live and learn. Hope this helps some. I'd be

happy to answer any question I can. Below is a shopping list. I did it from

memory so no guarantees.

Anyway you need the following from a donor car. In parenthesis is whether I got

it new or used.

Manual Transmission (used, not even rebuilt since the donor was fine)

Manual Transmission mount (used)

Pedal Assembly for Manual Transmission (used)

Shift tube (used)

Shift tube to transmission linkage and cover

Stick shift (used)

Stick shift base and bolts (used)

Flex tube from firewall to tranny (used)

Flywheel (used)

Pressure plate (new)

Clutch disc (new)

Release bearing (new)

Clutch cable tube (new 3/8" copper)

Craig Woolston

craig.woolston@lmco.com

'70 "Converted to Manual Transmission" Squareback

'71 Automatic Fastback ("Casper")-will get converted the next time the automatic

transmission acts up

'73 "Wish I Was Restored and Not Sitting in the Backyard" Sqaureback